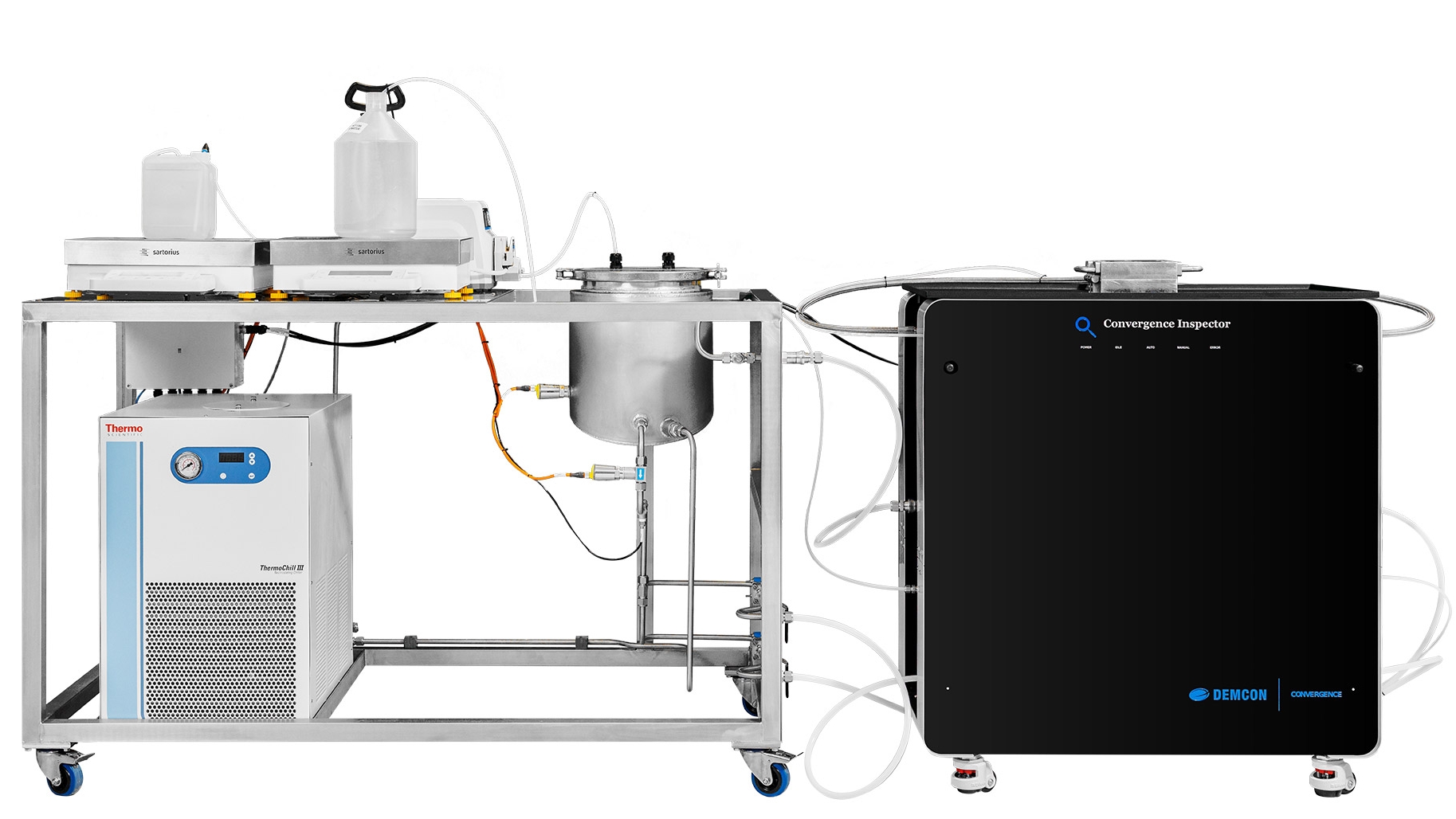

flexible, hygienic, and automated membrane technology.

Our systems are tailored for R&D and pilot production with a strong focus on hygienic design, automated control and equipped with software that lets you quickly set up experiments. Whether you're developing protein-rich foods, functional ingredients, or fermented dairy products, we offer craftsmanship, flexibility, and process control you can rely on.

We apply membrane technologies such as ultrafiltration (UF), microfiltration (MF), nanofiltration (NF), and reverse osmosis (RO), integrating third-party membrane modules selected for compatibility with food-grade applications.

applications of our membrane equipment:

- Protein concentration and fractionation – for dairy- (e.g. casein, whey), plant- (e.g. pea, soy), and egg-based proteins.

- Milk and dairy processing – including lactose reduction and protein standardization.

- Juice clarification and concentration – removing suspended solids, haze-forming compounds, and microbial content.

- Beer and wine clarification, stabilization, recovery and final filtration.

- Sugar and sweetener purification – using nanofiltration or diafiltration for selective removal.

- Beverage stabilization – through microbial reduction and pH control.

- Water reuse and ingredient recovery – improving sustainability and reducing waste streams.

key drivers of our technology:

- Product Safety & Hygienic Design

- Retention of Nutrients, Flavors & Aromas

- Selective Separation & Concentration of Components

- Energy-Efficient & Scalable Processing

- Traceability, Batch Control & Cleanability

- Compliance with Food-Grade Standards

your development partner.

Whether you're developing high-protein dairy concentrates, clear fruit juices, or plant-based beverages, we deliver the membrane test equipment you need.