advanced research in hydrogen and carbon capture.

Led by Dr. Faizan Ahmad, Teesside’s Hydrogen and Decarbonisation Technologies Research Group is part of the industry-led Net Zero Industry Innovation Centre, based in Middlesbrough. Their research focuses on:

- Carbon capture, utilisation and storage (CCUS)

- Hydrogen purification and production

- Membrane technology

- Direct air capture (DAC)

- Process modelling and simulation

The group is involved in several projects funded by funded by Innovate UK, ERDF, NERC and Royal Society. These projects include but are not limited to Project TENET, Project Calychar, Tees Valley Hydrogen Innovation Project, REHIP and Carbon Capture Ready for Energy from waste project.

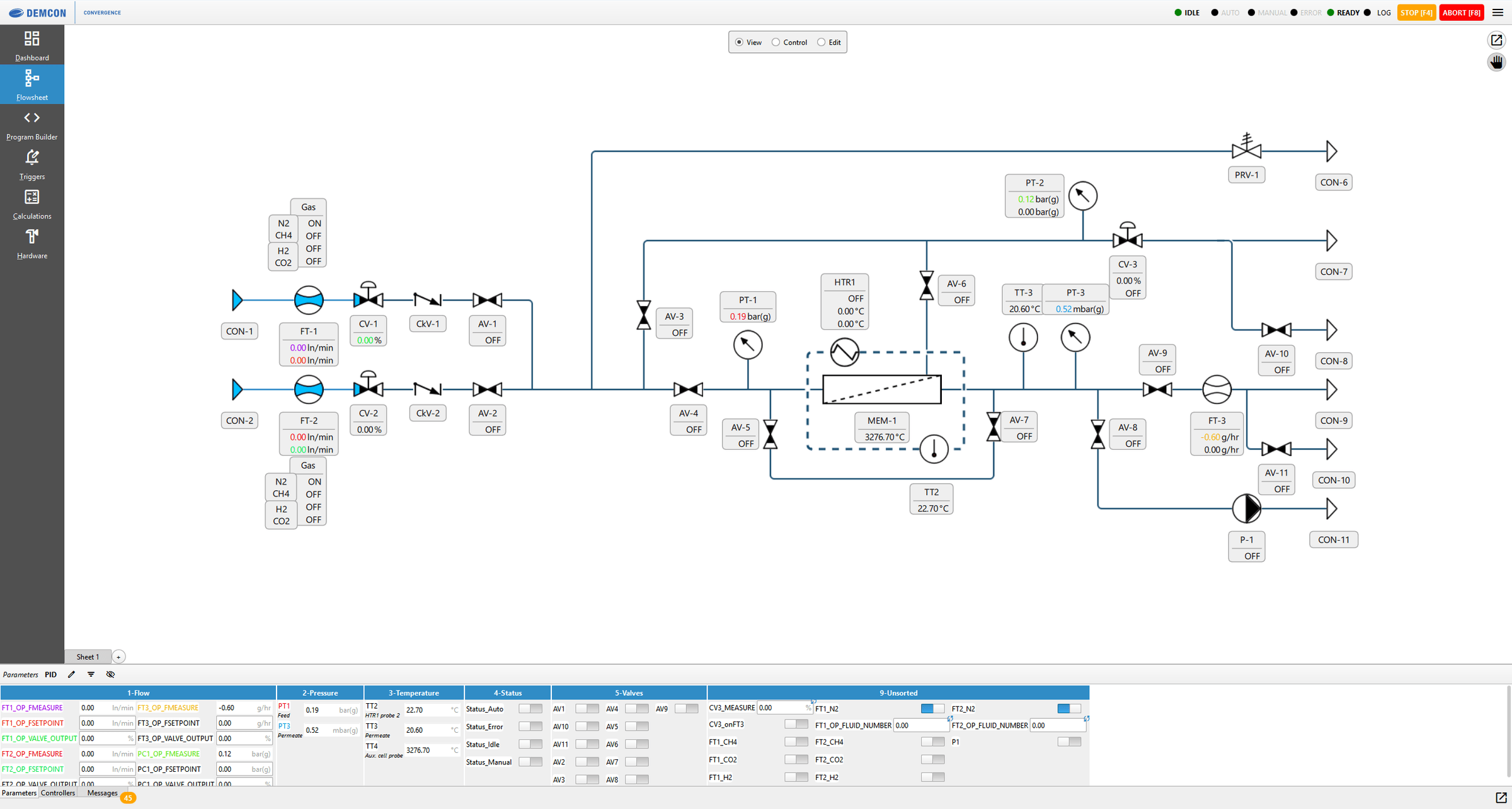

highlights of the GS Inspector:

- Two independent gas feed lines, each fully automated and individually flow rate controlled

- Coriolis Mass flow measurement in the permeate line for accurate performance analysis

- Equipped with a vacuum assisted line for precise time-lag measurements in membrane testing

- A separate heating box controls the temperature of the round disc module, which holds the membrane—enabling tests at various ambient temperatures.

- Designed for experiments up to 60 bar pressure, enabling high-pressure membrane testing.

The system incorporates high-end components from trusted manufacturers such as Bronkhorst and Burkert, ensuring reliability and precision.

the GS Inspector in action.

The Inspector is a sophisticated laboratory system developed for advanced gas permeation membrane research. At Teesside University, it is actively used by:

- Master’s students

- PhD candidates

- Visiting researchers (both Academia as well as Industry)

Users conduct a wide range of experiments, easily configured and executed using the system’s proprietary software.

During testing, Teesside University works with gas mixtures containing CO₂, H₂, and CH₄, allowing researchers to simulate real-world separation challenges and evaluate membrane performance under complex conditions.

unique software platform.

The system is equipped with our proprietary Flow Control Platform (FCP) software, designed to make experiment setup and execution intuitive and efficient. Features include:

- Experiment setup using graphical flow diagrams

- Real-time monitoring and logging of pressure, flow, and temperature

- Automated control sequences for valves, pumps, and heating elements

- Customizable workflows tailored to specific research protocols

- Remote access and control for flexible lab operation

- Integration with external sensors (such as a gas chromatography) for advanced data acquisition

a partnership for net zero innovation.

"With Demcon's GS Inspector, our team can push the boundaries of hydrogen purification and carbon capture research. It’s a vital tool in our journey toward a net-zero industry."