DENSsolutions MEMS devices for in-situ TEM.

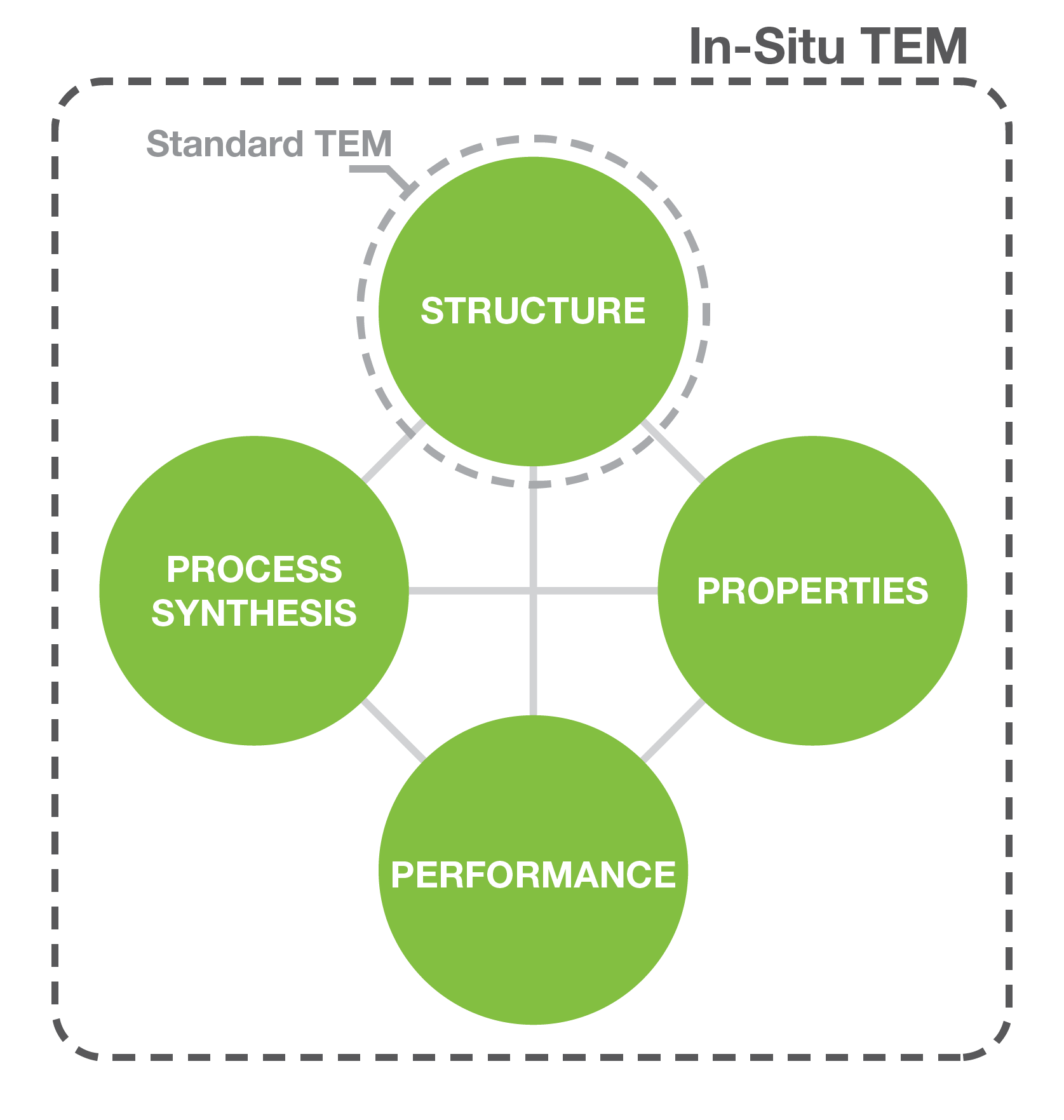

However, these conventional TEMs are still unable to support the whole research process. This is because a conventional TEM is unable to replicate real-world environmental conditions (heating, gas, liquid, etc.) as the sample is always introduced into a high vacuum, static environment. This fundamentally limits the value and obtainable benefits of a TEM.

Observing processes in-situ as they are occurring and under changing external stimuli is a solution that can negate these restrictions. DENSsolutions utilizes MEMS devices, the core of their systems, to control the sample’s environmental surroundings and replicate real-life application conditions inside a TEM (see Figure 1). The introduction of in-situ capabilities into a TEM, transforms the system from a static imaging tool into a multi-functional laboratory.

gas supply systems.

Demcon convergence operates as a private label manufacturer for DENSsolutions. It has co-designed and builds systems such as the Gas Supply Systems, Gas Volumetric Blending systems and vaporizers that are integrated into the DENSsolutions In-Situ TEM Climate system.

In the development phase we designed the flow control process, the electrical design, the exterior design and the mechanical design for the low-volume microfluidic flow blocks. Instrumentation and component selection, risk analysis, the software control system, assembly work instructions, test- and acceptance protocols and change control procedures have all been developed and adjusted in close collaboration with DENSsolutions.