no more manual intervention.

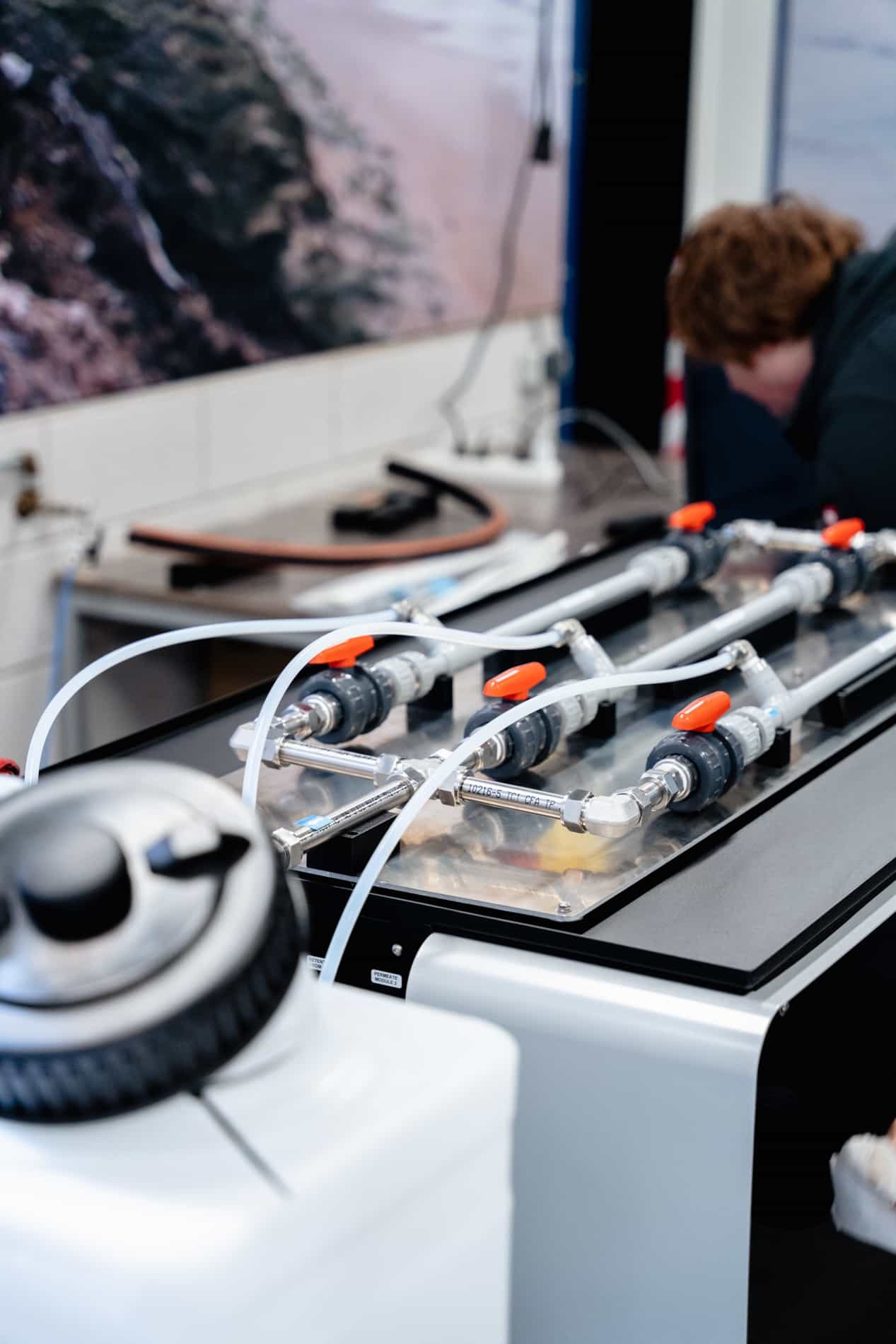

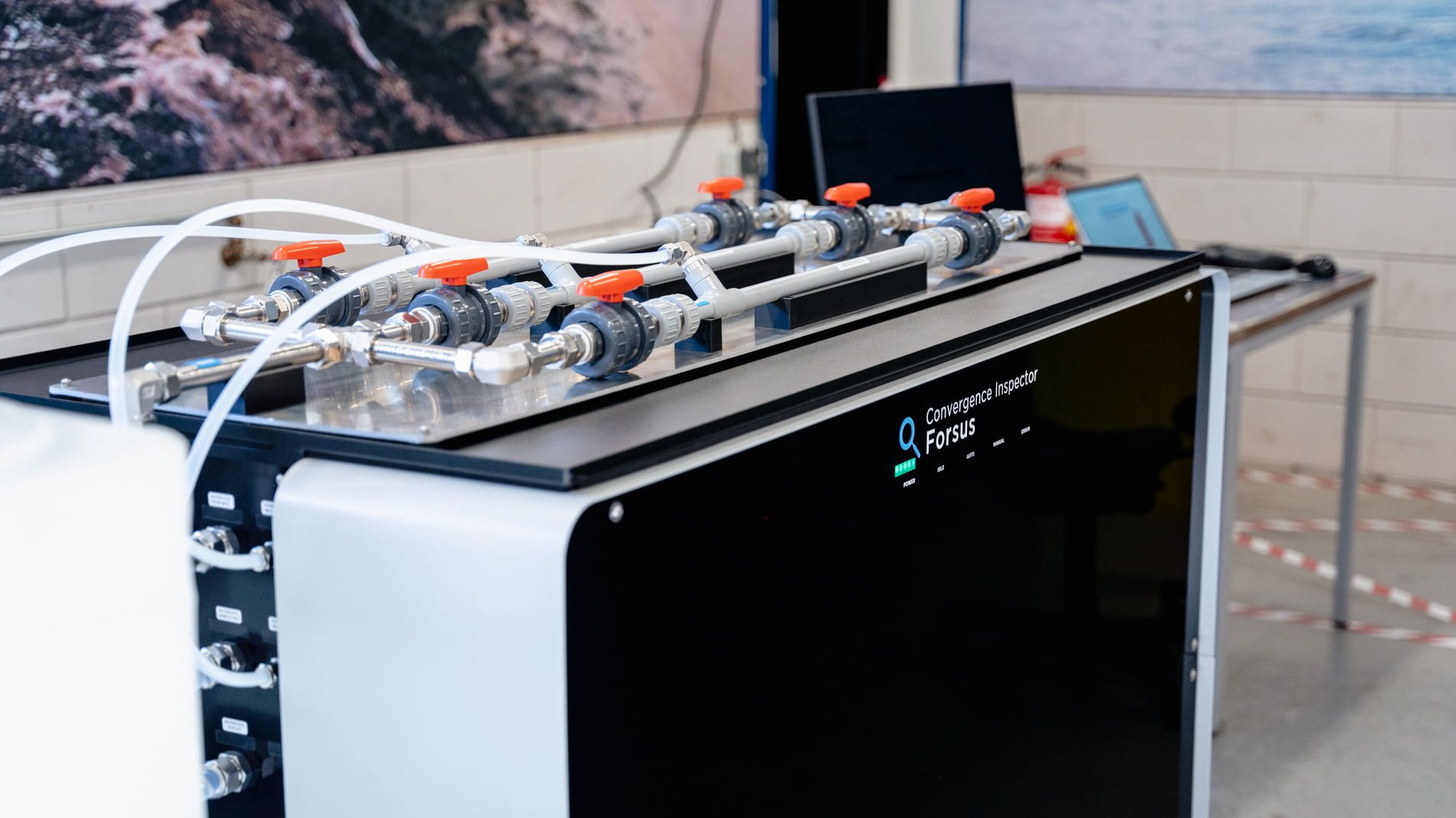

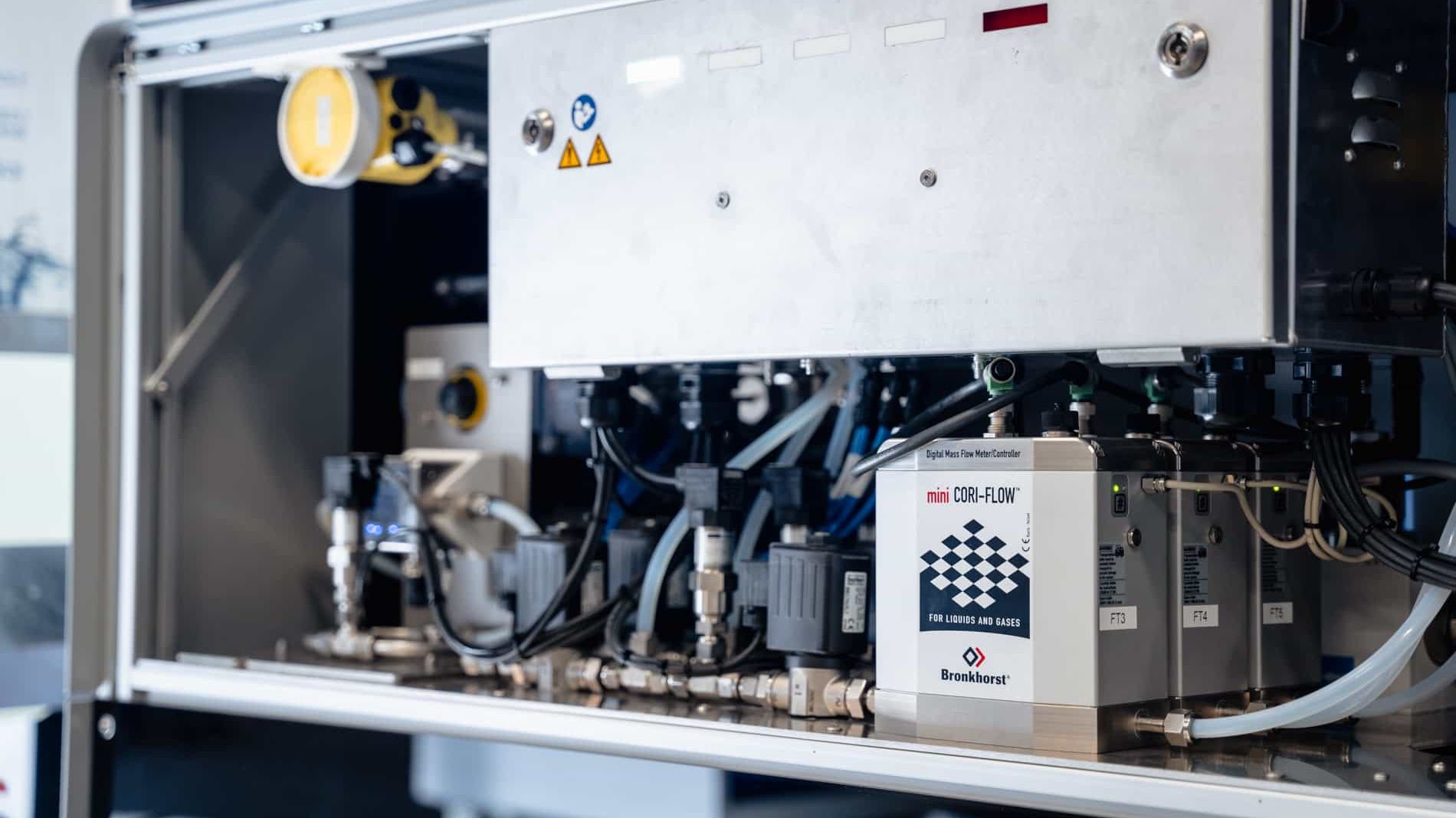

Demcon convergence has designed a fully automated pilot-scale ultrafiltration system, equipped with three membranes operating in parallel. This system is revolutionizing the field with its comprehensive automation, ensuring optimal performance and efficiency. The system excels in regulating the trans-membrane pressure, crossflow velocity, and permeate flow, enabling precise control over the filtration process.

With a capacity of 2800 L/h feed flow and the capability to control pressures up to 8 bar(g), the system is engineered to tackle even the most challenging filtration tasks. Additionally, the system incorporates an automatic backwash feature, eliminating the need for manual intervention. Integrated automatic valves are also included for sample collection, pH monitoring, and heating control.

The system can seamlessly switch between two vessels to conduct research with different media and is equipped with a tap water connection to facilitate automatic flushing between experiments.

protocols and change control procedures have all been developed and adjusted in close collaboration with DENSsolutions.